Smart logistics concept creates synergies

With an intelligent logistics system for fly ash, EP Power Minerals is reconciling the needs of the German energy industry with those of British subsidiary Power Minerals Ltd.

Rebirth of Coal

For more than 50 years, fly ash has been a highly sought-after certified binder component both in Germany and abroad. As a main component in cement and as a concrete additive, it makes a considerable contribution to environmental protection and the conservation of natural resources.

In the marketing of fly ash, a typical peculiarity arises with the quantity problem: the available quantity of fly ash is not the result of supply and demand on the construction materials market, but rather results from the demand for energy from hard coal fired power plants.

The coal phase-out law passed by the German Parliament in 2020 has had a direct impact on the amount of hard coal fly ash produced in Germany in recent years. In response, manufacturers of concrete and the cement industry have used alternative materials or changed concrete formulas.

The COVID crisis, supply problems on the world markets and the war in Ukraine are leading to uncertainties on the global energy markets. Against the given background conditions, hard coal has again played an important role in the energy mix since 2021. Hard coal fired power plants are available in the short term as a backup when the wind is not blowing, the sun is not shining and natural gas is not cost-effective.

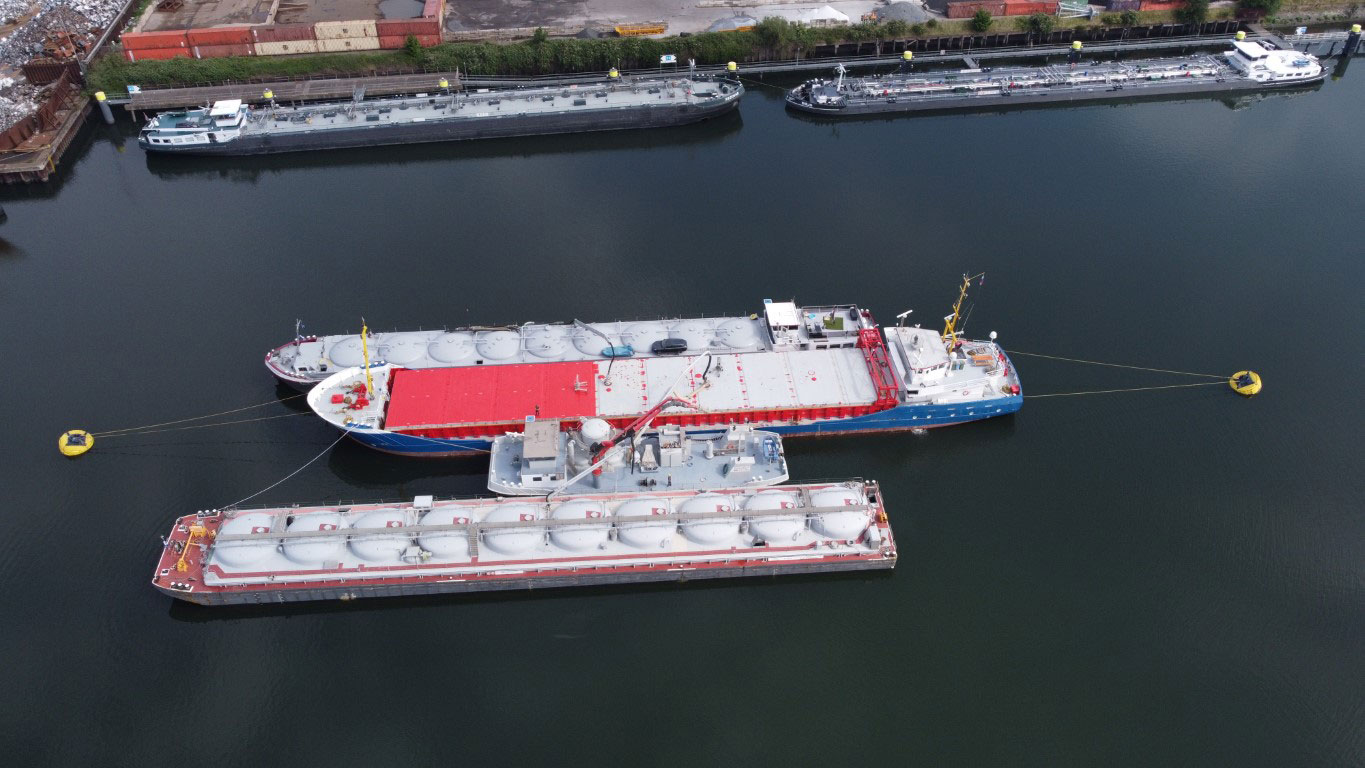

Logistics chain combines inland and seagoing vessels with silo push barge and pumping vessel

Together with service providers from inland and maritime shipping, new delivery strategies were developed for the UK. One successfully implemented idea involves loading inland silo vessels at selected power plants in the Ruhr area, transferring the fly ash ship-to-ship to coasters at an ARA port (Amsterdam, Rotterdam or Antwerp), and supplying fly ash to various receiving stations in the UK by seagoing vessel at the end of the logistics chain.

As this type of fly ash logistics is a just-in-time business, a silo push barge is used to eliminate risks in the logistics chain to avoid demurrage and waiting time costs. The combination of a floating storage facility with inland silo barges arriving in parallel with the loading of the coasters enables cost-optimized shipping of fly ash from German power plants to consignees in the UK.

Pumping vessel handles displacement air properly

When blowing fly ash both from the silo push barge and directly from other silo barges into the coaster, a dust removal facility has to be provided in order to process the dust-laden displacement air properly. For this purpose, a pumping vessel from Binnenlloyd Maastricht B.V. is connected between the silo barge and the coaster. In addition to moving the material, the pumping vessel also extracts and filters the displacement air, thus ensuring that overpressure in the coaster’s hold is avoided and at the same time making dust-free working possible.